- Home

- Products

- Dew Point

- Dew Point Sensor

- Dew Point Transmitter (BDTH01-01)

Dew Point Transmitter

This transmitter (sensor) measures dew point in the dry compressed air from -60 to +60 °C Td. It is designed for reliable and accurate analysis even in high pressure industrial processes. By installing the dew point sensor, people can monitor the dew point and maintain an optimal humidity condition. It is used to meet the needs for industrial applications, such as compressed air system, pharmaceutical industry, and food processing facility.

Dew Point Transmitter / Sensor

- Range: -60°C to 60°C

- Accurate and reliable measurement

- Designed for compressed air, drying processes and air pressure pipelines

During coating process, dew point meter with automatic temperature compensation and manual periodic calibration is essential to analyze the ideal ambient conditions because moisture can affect the success of the surface coating. Obviously, dew point temperature plays an important role in many industrial processes. BDTH01-01 dew point transducer is equipped with both 4-20mA transmitter and RS485 (Modbus RTU) output. Its user-friendly design makes your installation and operation simple. There are several features that make this dew point meter useful and cost-effective. First of all, wide dew point ranges, covering an overall range from -60 °C to +60 °C, are available. Second, it provides you with multiple process connections. Third, its rugged stainless steel housing offers protection to IP65. Last but not least, it provides long-term stability and reliability at a competitive price.

| Dew Point Range | -20 to 60ºC Td -40 to 60ºC Td -60 to 60ºC Td |

| Accuracy | ±2ºC Td@25ºC (-40 to 60ºC Td) ±3ºC Td@25ºC (-60 to -40ºC Td) |

| Temperature Compensation | Yes |

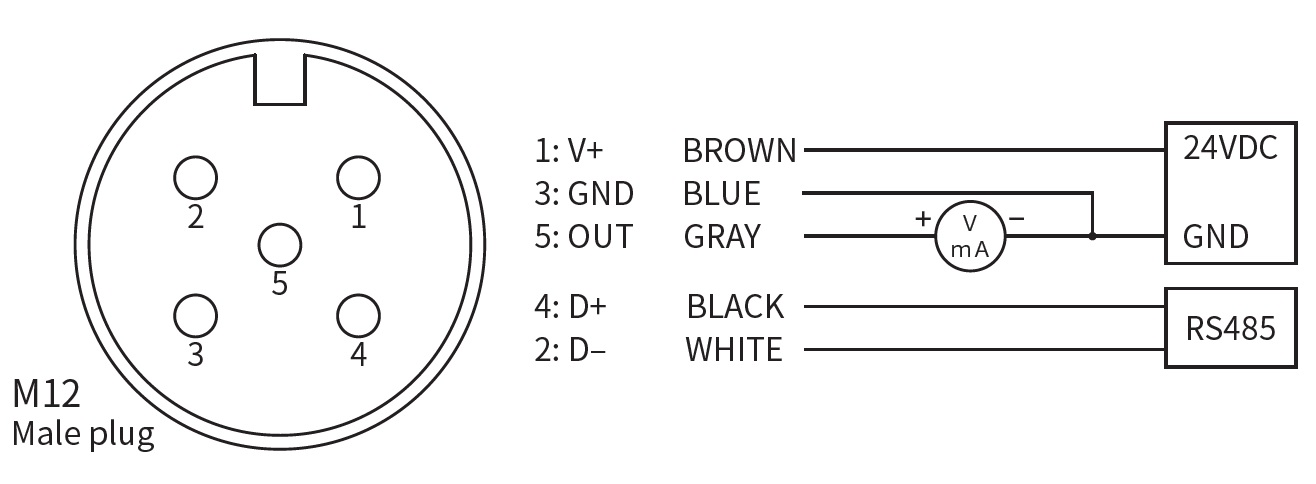

| Current Output | 4...20mA |

| Voltage Output | 0...1V / 5V / 10V |

| Load Resistance | RL < 400 ohm (4 ... 20 mA output) RL > 2k ohm (0 ... 1 V output) RL > 10k ohm (0 ... 5 V or 0 ... 10 V output) |

| Digital Output | RS485 Modbus RTU |

| Supply Voltage | 24VDC |

| Housing Material | 304 stainless steel |

| Process Pressure | 10MPa maximum |

| Housing Protection | IP65 |

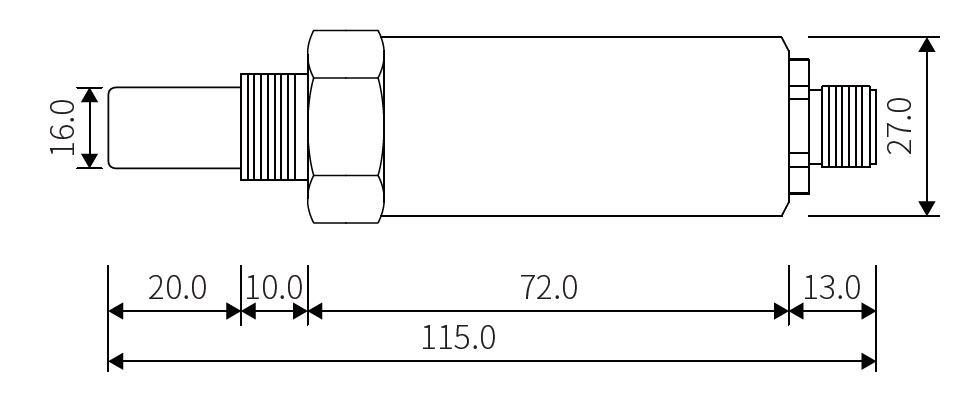

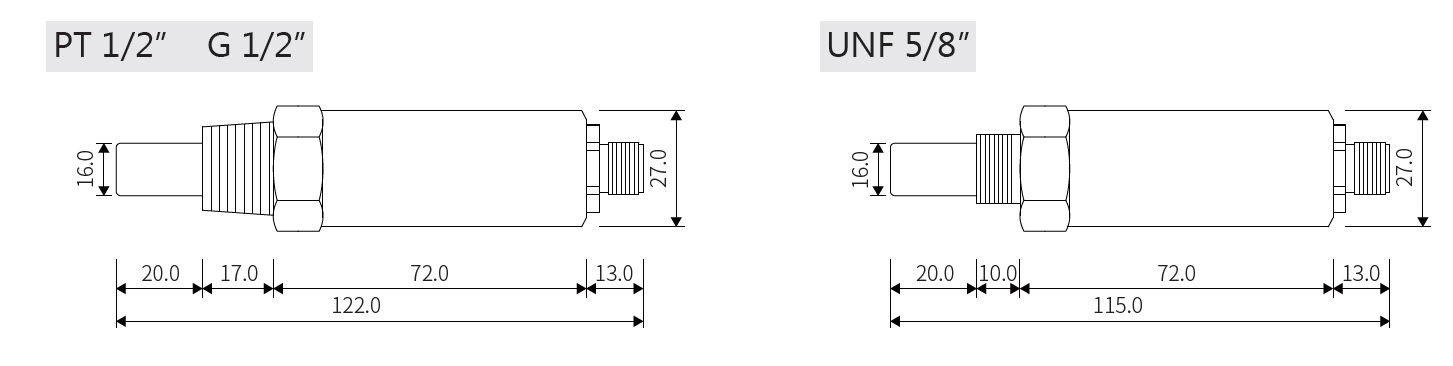

| Process Connections | PT1/2" , G1/2" , UNF5/8" |

| Electrical Connection | M12, 5 pin |

| Sensor Protection | sintered filter |

| Operating Temperature | -40 to 85ºC (-40 to 185ºF) |

| Electromagnetic Compatibility | EN 61326-1:2013 Emission CISPR 11:2009+A1:2010 Group1 Class B EN 61326-1:2013 Immunity IEC 61000-4-2:2008 IEC 61000-4-3:2006+A1:2007+A2:2010 IEC 61000-4-8:2009 |

Compressed air is often used in industrial applications for a diversity of purposes, such as drying, blowing, mixing, and cleaning. When it comes to monitoring compressed air, dew point sensor can be a critical role throughout the entire industrial process. Take food industry for example, compressed air has direct or indirect contact with products in the food supply chain and finished products. Products may be contaminated because of the moisture in compressed air. To prevent products from deteriorating, compressed air must be dry and clean. For the same reason, compressed air system need dry and clean air, too. When moisture gets into compressed air, it may contaminate the compressed air and cause damages, such as icing, rusting, and wear parts. Rust can lead to disintegration of materials, especially metals. If compressed air pipes are corroded, compressed air may leak. Also, having moisture in compressed air can have negative influence on process and product quality. So, selecting a dew point transmitter with suitable measuring range is necessary. Monitoring dew point not only can ensure the working life of your machinery and the quality of final product, but prevent your products from being damaged.

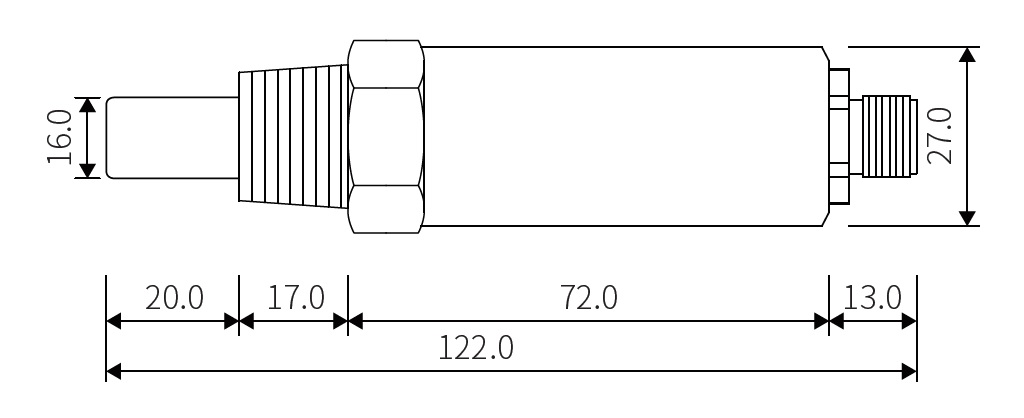

UNF5/8"