- Home

- Products

- Pressure Sensor

- Digital Pressure Gauge

- Digital Pressure Gauge (BDP01-01)

Digital Pressure Gauge

Digital pressure gauge displays the accurate readings while measuring a wide range of liquid or gas pressure in general industrial applications, such as laboratory, pharmaceutical, manufacturing, pump systems, and process control. It also provides a stable and economic solution at an affordable price.

Digital Pressure Gauge / Sensor / Switch

- Red LED display readings

- Units switching between bar, psi, kPa and MPa

- Quality, economical solution for measuring pressure

Digital pressure gauge is a high accuracy device with switching output that can be actuated by a change in the pressure of liquids or gases. A wide range of digital signals, such as IO-Link, RS485, RS232, I²C and USB, may be used for some digital pressure instruments.

Generally, Digital pressure gauge has gauge, absolute, differential or sealed pressure types. Gauge type, for example, is used to measure the pressure relative to standard atmospheric pressure. For absolute type, the reference point is a perfect vacuum.

Our digital pressure gauge is designed for gauge pressure measurement in various units including bar, PSI, kPa and MPa. Different pressure units can be used to meet the need of different applications or countries. For example, the unit “psi” is often used in America.

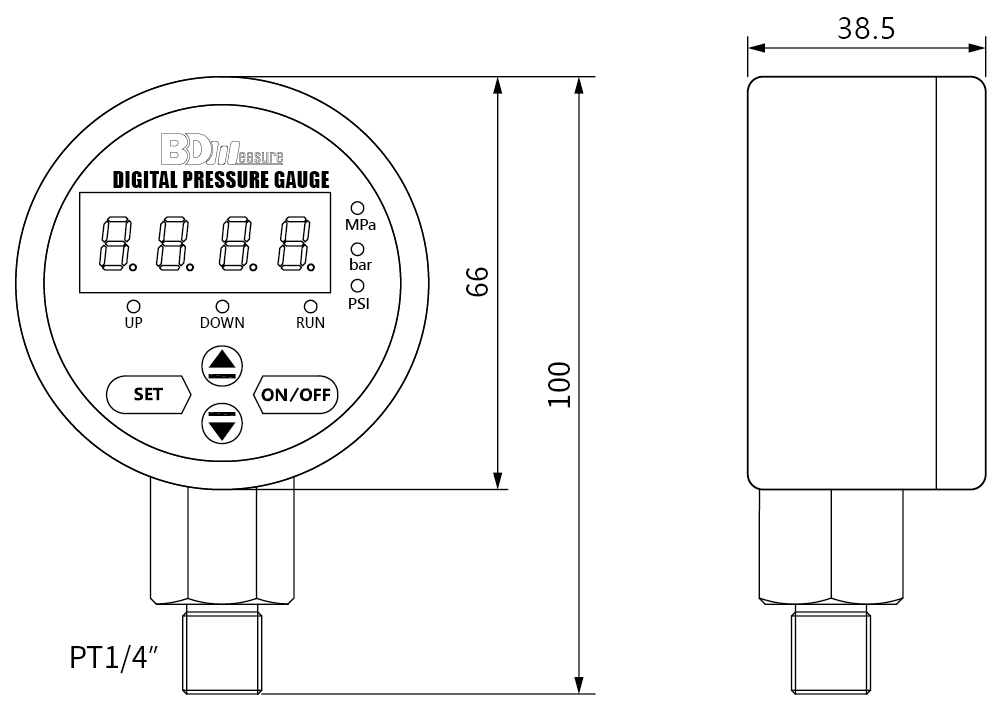

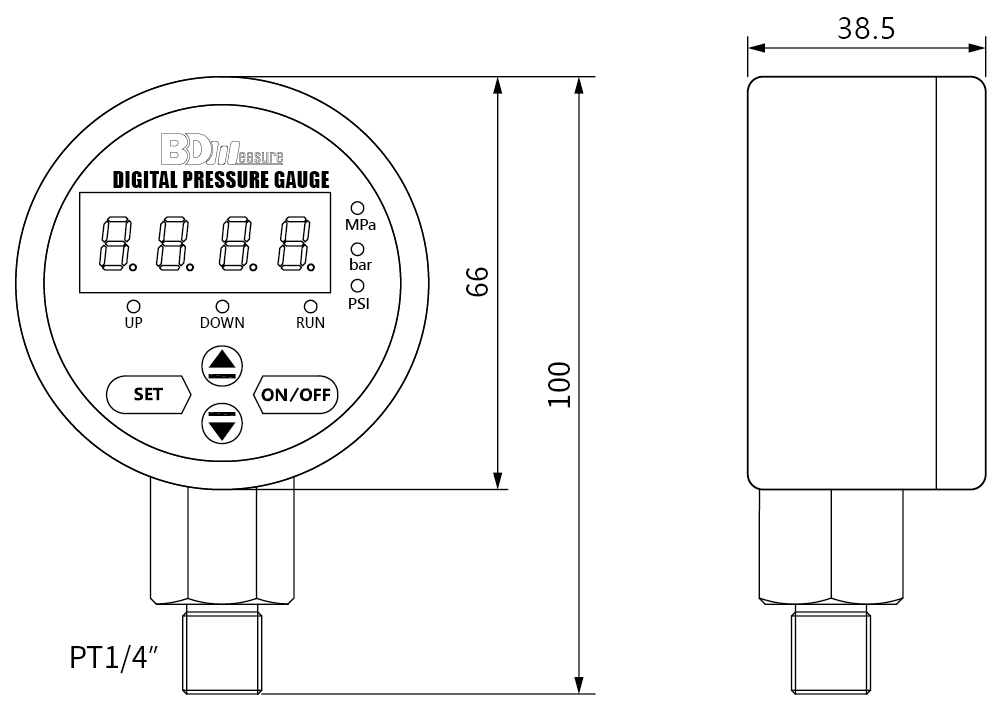

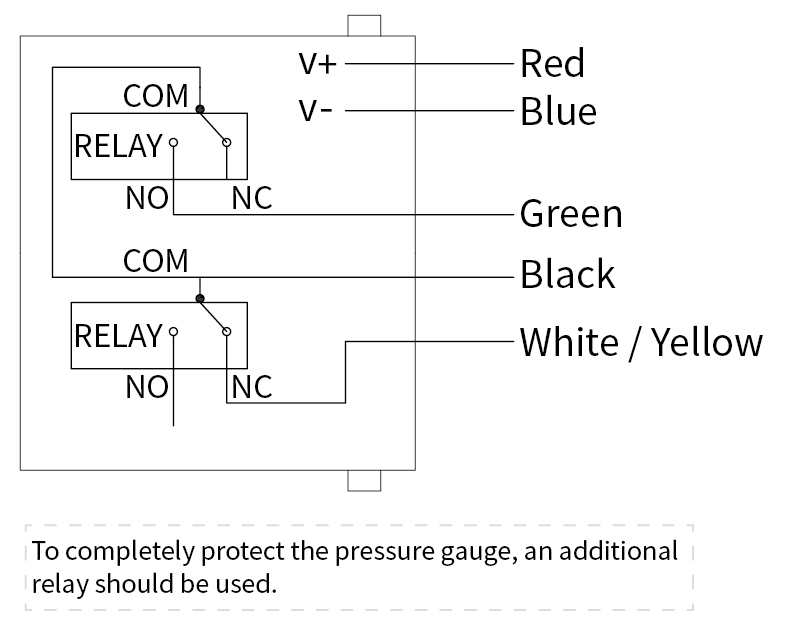

A variety of pressure ranges, such as -100…0 kPa (vacuum), 10…100 kPa (low pressure), 0.16…4 MPa (general pressure) and 6…60 MPa (high pressure), are available on our digital pressure switches. Our BDP01-01 is small size and ease of use. It offers stability over dial pressure gauges because digital pressure gauges reduce the use of mechanical actuation. The 4-digit seven segment LED display, minimizing the potential for error in readings, provides clear readability in poor light, even in dark. In addition, there are two adjustable switches with relay outputs for high and low alarm limits. You can set one or two alarms by the push-buttons of front panel that are accesses to the programming menu.

| Pressure Ranges (The maximum operating pressure of your application should not exceed 80% of the pressure range) |

Negative Gauge Pressure: -100…0kPa |

| Low Gauge Pressure: 0…10/16/25/40/60/100kPa |

|

| General Gauge Pressure: 0…0.16/0.25/0.4/0.6/1/1.6/2.5/4MPa |

|

| High Gauge Pressure: 0…6/10/16/25/40/60MPa |

|

| Process Media | All liquids and gases which are compatible with 304 stainless steel |

| Display | 4-digit LED |

| Pressure Units | For negative and low gauge pressure: Unit switching between the units bar, PSI, and kPa |

| For general and high gauge pressure: Unit switching between the units bar, PSI, and MPa |

|

| Display Rate | 8 times per second |

| Relay Output | Two adjustable setpoint relays |

| Contact Rating | 220VAC, 3A (Resistive load) |

| Hysteresis | Adjustable |

| Overpressure | ≤ 10MPa, 2 x range >10MPa, 1.5 x range |

| Accuracy | 0.5%FS |

| Case Size | 60mm |

| Process Connections | PT1/4" , PT1/2" , NPT1/4" , NPT1/2", G1/4" , G1/2" , M20x1.5 (others on request) |

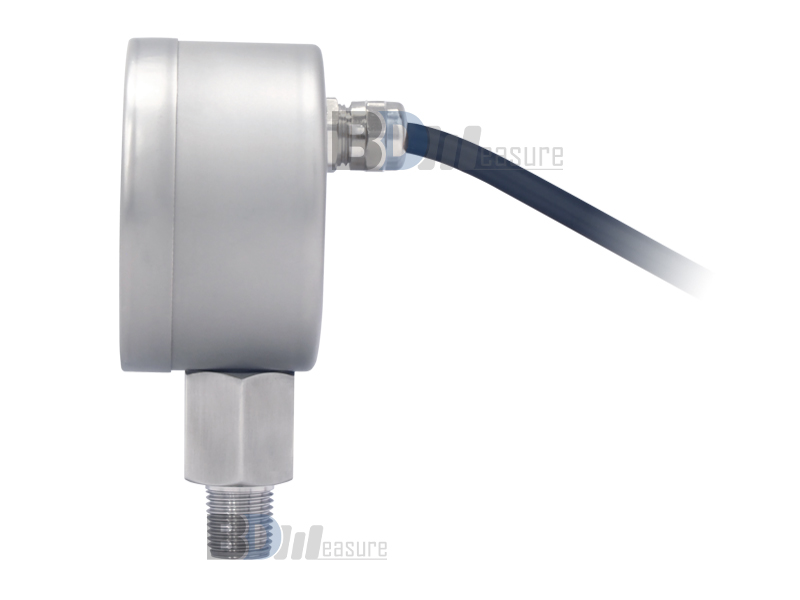

| Housing Material | 304 stainless steel case |

| Electrical Connector | Waterproof connector and a 60cm cable |

| Supply Voltage | 24VDC |

| Operating Temperature | -20 to 65°C |

| Housing Protection | IP65 |

Commonly, a digital pressure gauge uses a piezoresistive pressure sensing element to respond to changes in pressure. When the diaphragm is deformed by the pressure, the resistance of the strain gauge changes. As a result of this effect, digital pressure gauges can convert the applied pressure into signals and display the readouts numerically. Pressure is one of the most commonly measured quantities for safety and quality control in various fields. When it comes to measuring and monitoring pressure, accuracy plays an important role in industrial applications. Generally, analog pressure gauges are often misread because viewing the value from a needle on a pressure scale can result in parallax error. However, there are no parallax problems by using digital pressure gauges because of their digital readout. They display a reading of pressure value directly on site, rather than transmitting the signals to a control or display device. Selecting a suitable digital pressure gauge can keep your equipment running properly and avoid excessive maintenance. To maintain the operating life of digital pressure gauges, it is recommended to use with four-fifths of the upper limit value of the pressure range.