- Home

- Products

- Pressure Sensor

- Pressure Transmitter

- Pressure Transmitter (BDP02-01)

Pressure Transmitter

Pressure transmitter is a sensor that provides real-time measurements. To ensure the safety of working environment, many people monitor or control pressure to achieve their desired value. Pump systems, Compressor, industrial process monitoring, laboratory and petroleum as well as other applications all use electronic pressure sensors as reliable devices for their liquid or gas pressure measurement.

Pressure Transmitter / Sensor

- Offer quality, reliable pressure transducers and solutions

- Accurate measurement for pressure or level of gases and liquids

BDP02-01 pressure sensor is a device that has a sensing element and converts the applied force into electrical output signal. With a response time of ≤ 5 ms, the pressure transmitter is well-suited for the majority of industrial applications.

Pressure transmitters, as known as pressure transducers, are used in various applications requiring precise pressure measurement. Gauge pressure sensors, for example, are ideal for controlling and monitoring the compressed air pressure or open tank level.

Our pressure transmitter provides a variety of outputs and measuring ranges. Many process connections are available for application flexibility, which allows you to select right pressure transmitter for your application requirement.

| Pressure Ranges (The maximum operating pressure of your application should not exceed 80% of the pressure range) |

Negative Gauge Pressure: -100…0kPa |

| Low Gauge Pressure: 0…5/10/16/25/40/60/100kPa |

|

| General Gauge Pressure: 0…0.16/0.25/0.4/0.6/1/1.6/2.5/4MPa |

|

| High Gauge Pressure: 0…6/10/16/25/40MPa |

|

| Overpressure | ≤ 10MPa, 2 x range >10MPa, 1.5 x range |

| Response Time | ≤ 5ms |

| Accuracy | 0.5%FS |

| Stability | ±0.25%FS/year at reference conditions |

| Zero Drift | ±0.02% FS/°C (Typ.), ±0.05% FS/°C (Max.) |

| Span Drift | ±0.02% FS/°C (Typ.), ±0.05% FS/°C (Max.) |

| Supply Voltage | 12…28VDC (24VDC, standard) |

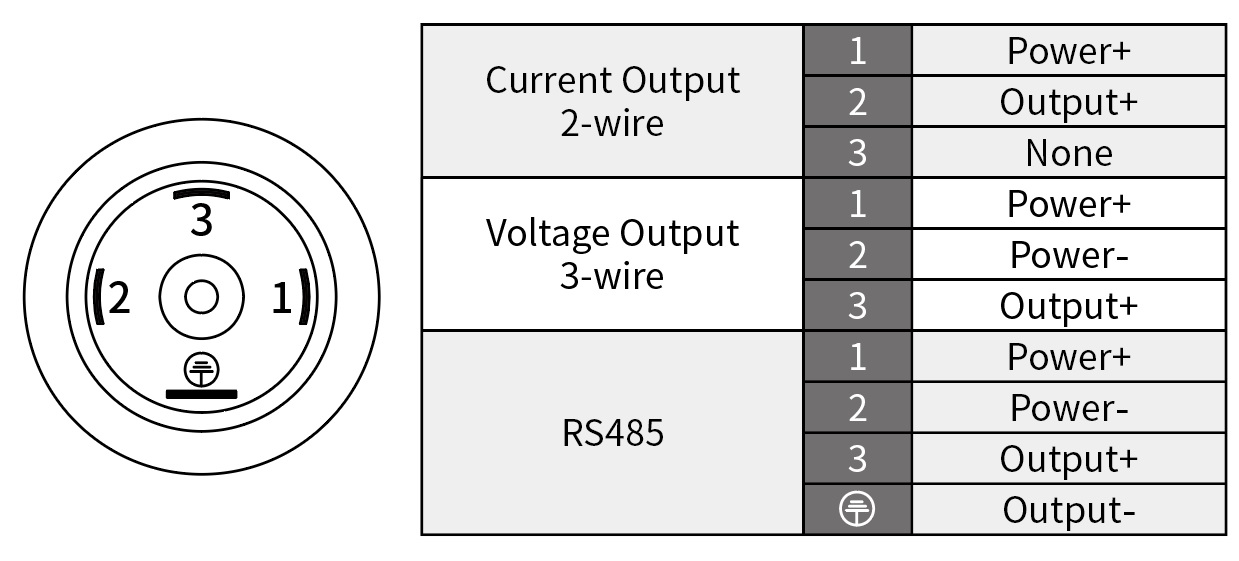

| Output Signals | 4…20mA / RS485 / 0…5V / 0…10V |

| Operating Temperature | -40 to 80°C |

| Compensated Temperature | -10 to 70°C |

| Storage Temperature | -20 to 60°C |

| Electrical Protection | Reversed polarity protection for 4…20mA output EMI prevention |

| Housing Protection | IP65(DIN connector) , IP67(Cable) |

| Process Media | All fluids compatible with stainless steel |

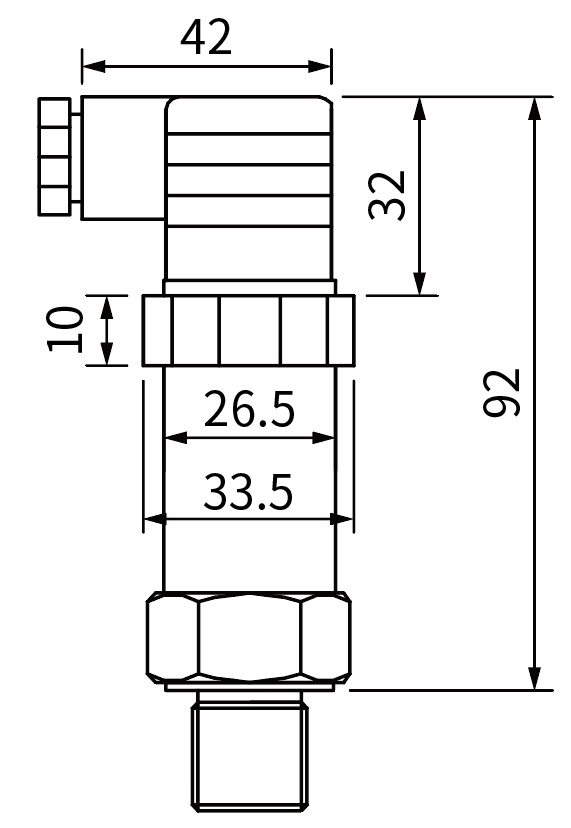

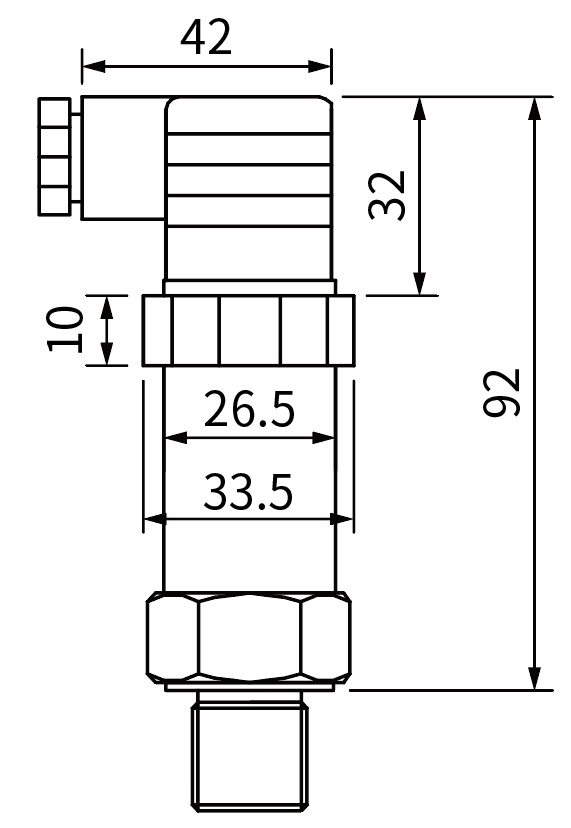

| Process Connections | PT1/4" , PT1/2" , NPT1/4" , NPT1/2" , G1/4" , G1/2" , M20x1.5 (others on request) |

| Housing Material | 304 stainless steel |

| Wetted Parts Material | 304 stainless steel - Process Connection |

| 316L stainless steel - Diaphragm |

Pressure usually plays an important role in various industrial processes. It is one of the most broadly measured variables in the process industries. The pressure transmitter, also known as hydrostatic device while measuring liquid level, is a sensor that not only can be used to measure fluid pressure, but also liquid level. It converts the physical variable pressure into an electrical output signal, which is then immediately transmitted to a device like digital panel meter, computer, PLC or HMI to ensure the result is delivered in real-time. A common application is open tank liquid level measurement, for example. It means that the tank or container is open to the atmosphere. When employing the pressure transmitter, you can install the device on the side of the bottom of a tank to get an accurate reading. The pressure sensor will detect the actual level of fluid in the tank and give the resulting liquid level. Please note that if the tank is closed (pressurized), a gauge pressure transmitter will not work because the sensor will measure both the pressure exerted by the liquid and the vapor pressure above the liquid.

To briefly introduce the principle of the pressure transmitter, here we give an example of a common pressure sensor which has a pressure sensitive diaphragm with strain gauges bonded onto it. This kind of pressure transmitter uses the strain gauge to measure the force acting on them. When the strain gauge is deformed by the applied force, this deformation of the strain gauge causes a change in resistance. Then, through the designed circuit, the change of resistance is converted to voltage or current variations resulting in a corresponding output. Once the applied pressure releases, the strain gauge returns to its original state.

It is important to select a pressure transducer that is suitable for the application. By mounting it, you can measure and monitor the pressure or liquid level to maintain an optimal value.