- Home

- Products

- Level Sensor

- Ultrasonic Level Transmitter

- Ultrasonic Liquid Level Transmitter (BDL02-01)

Ultrasonic Liquid Level Transmitter

Ultrasonic liquid level sensor is an ultrasonic gauging device for continuously liquid level measurement without making physical contact with the material. It is typically simple to install and easy to use. It is used in a wide range of applications, such as food and beverage industries, water and wastewater treatment systems, liquid storage vessels, level-based pump control, etc.

Ultrasonic Liquid Level Transmitter

- Time-of-Flight principle

- Used for open tank applications

- Offer accurate and reliable level measurement

Ultrasonic liquid level transducers, using sound wave technology, are sensors that provide non-contact continuous distance measurement.

BDL02-01 Ultrasonic liquid level transmitter provides various measuring ranges for you to select depending on your requirements. It is non-contact continuous level measurement and suitable for measuring clam, smooth surface of liquids that do not contain foam or vapors in open tanks or other vessel. Since the speed of sound is temperature dependent, the transducer includes an integral temperature sensing element. The hotter the air is, the quicker a sound wave travels. Therefore, an integral temperature sensing element can help the ultrasonic transducer compensate for this effect.

Our ultrasonic liquid level sensors are equipped with 4-20mA output signal or RS485 Modbus RTU communication for inputting to devices such as digital displays, PLC, or others. The IP68 water intrusion standard makes them ideal for indoor and outdoor application. They are not only low maintenance but also price-favorable.

| Measuring Ranges | 0.2…1 m | 0.2…2 m | 0.2…3 m | 0.2…4 m | 0.2…5 m |

| Blind Zone | 0.2 m | 0.2 m | 0.2 m | 0.2 m | 0.2 m |

| Frequency | 64kHz | 64kHz | 64kHz | 64kHz | 64kHz |

| Field Angle | 15° | 15° | 15° | 15° | 15° |

| Measuring Ranges | 0.3…6 m | 0.3…7 m | 0.3…8 m | 0.3…9 m | 0.3…10 m |

| Blind Zone | 0.3 m | 0.3 m | 0.3 m | 0.3 m | 0.3 m |

| Frequency | 40kHz | 40kHz | 40kHz | 40kHz | 40kHz |

| Field Angle | 24° | 24° | 24° | 24° | 24° |

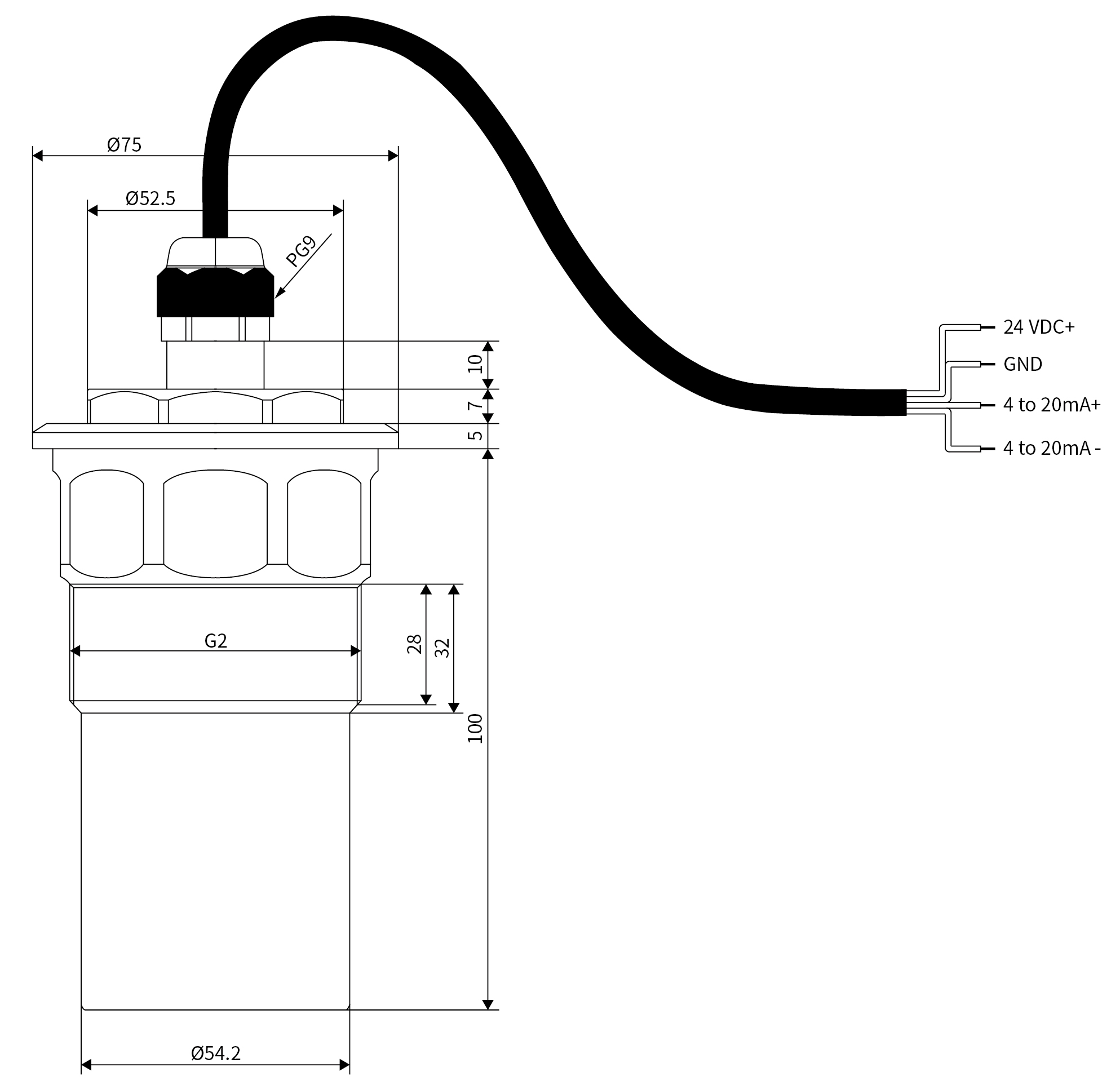

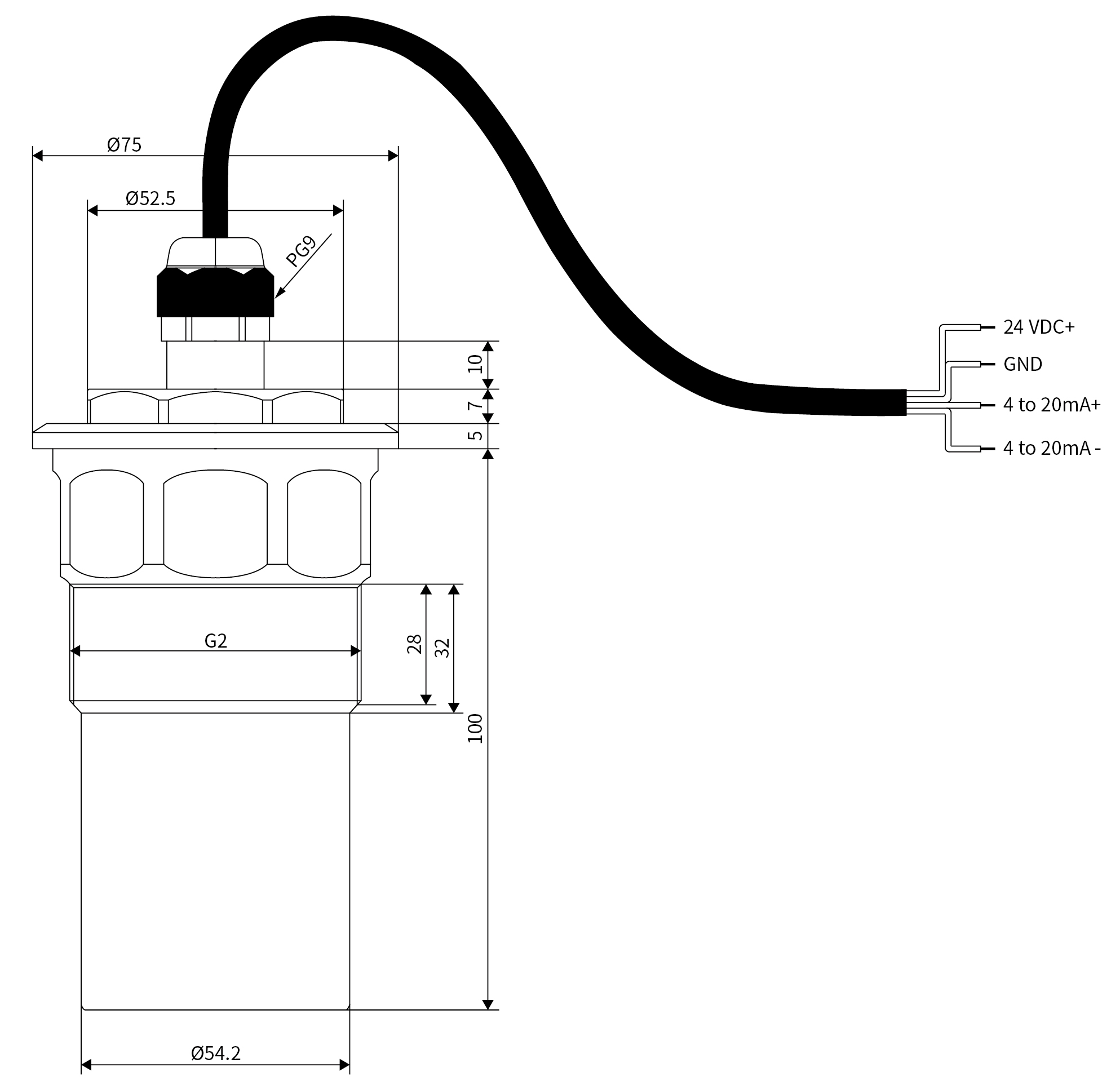

| Process Connection | G2A |

| Output | 4…20mA / RS485 Modbus RTU |

| Accuracy | ±0.5%FS |

| Temperature Compensation | Yes |

| Housing Material | POM |

| Process Temperature | -20 to 60℃ |

| Process Pressure | Normal atmospheric pressure |

| Supply Voltage | 24VDC |

| Cable Length | 5m |

| Housing Protection | IP68 |

Level is among the most frequently measured variables in industrial processes. Additionally, accurate level measurement supports safer and more efficient operations. It can prevent the storage tank from overfilling or protect the pumps from running out of water.

When it comes to measuring continuous level of the liquids in an open tank or other containers, there are many instruments you can choose from. Take ultrasonic liquid level transmitters for example. They do not come in contact with the target substance. Ultrasonic liquid level sensors are low maintenance and cost-effective devices that measure accurate and reliable level readings without affecting your product. They rely on sound waves to determine liquid level by measuring the distance between the transducers installed at the top of the tank and the surface of liquid. The sensor emits the ultrasonic pulses that face down to the material. The liquid surface reflects these ultrasonic impulses, and then the sound waves turn back to the transducer. When the transmitter detects the ultrasonic signal again, it will calculate the time of flight to determine the height of the material in the container.

To avoid erroneous reflections, the sensor should be mounted in a location that is unobstructed from the sensor to the target. If there are obstructions, such as ladders, pipes, fitting, mixers or other instruments inside the tank, they can cause multiple and false reflections. If your tank roof is domed, please avoid installing the ultrasonic liquid level transmitter in the center of the domed top because the domed top would behave like a parabolic reflector that may result in undesired echoes. If the levels of relevant liquids are not measured or controlled properly, it may create unwanted changes in product quality, even damage production equipment. Because there is not universal instrument for liquid level measurement, proper selection and installation of the instruments are critical for achieving precise measurement in liquid level monitoring system.