- Home

- Products

- Level Sensor

- Optical Level Switch

- Optical Liquid Level Switch (Polyamide) (BDL01-01)

Optical Liquid Level Switch (Polyamide)

If you need a low-cost and small size device to measure the liquid levels for industrial application where space is limited, an optical level switch might be a perfect candidate. Optical liquid level sensors are suitable for water level measuring and monitoring. Our optical level switches are no moving parts to cause unreliability, and these small units are ideal for a wide range of applications, such as home appliances, food and beverage industries, hydraulic reservoirs, and pharmaceutical systems.

Optical Liquid Level Sensor / Switch

- Small, compact and reliable

- Low cost sensing electronics

- Long operating life with no moving parts

An optical level sensor uses the principle of light reflection. The light in a prism is emitted from an infrared LED and reflected back to the receiver directly when the sensor is in air. However, when the sensor tip is immersed in liquid, most of light is lost in liquid, leaving little to return back to the receiver.

It is a suitable product for you to satisfy your needs if you want to install a liquid level sensor in areas where space is limited. The Series BDL01 Optical Level Switches are designed for detecting and monitoring point level. It is a kind of low price liquid level sensor. The electro-optic level switch measures the high or low of most liquid, water-based and oil. For detecting minimum or maximum level, the sensor must be installed at the desired height. Three optional materials, polyamide, polysulfone and SS316L provide application flexibility. This sensor requires a power supply of between 10-30 VDC. The level output modes are normally open when the sensor tip is dry and closed in presence of liquid. It not only can be easily mounted, but provides rapid response while employing.

| Model | BDL01-01 |

| Housing Material | Polyamide |

| Prism Material | Polyamide |

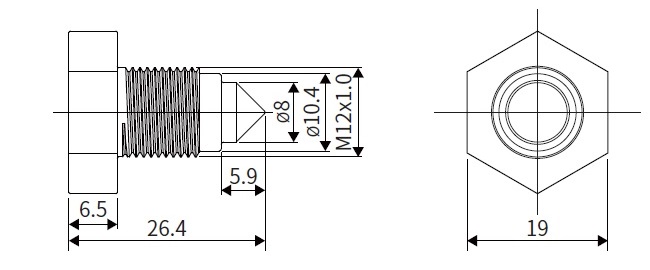

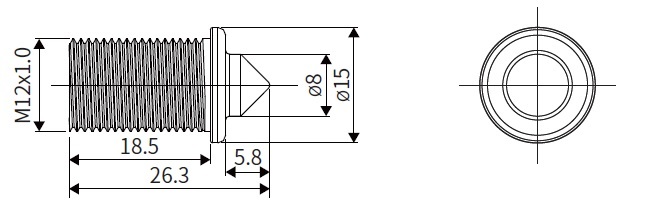

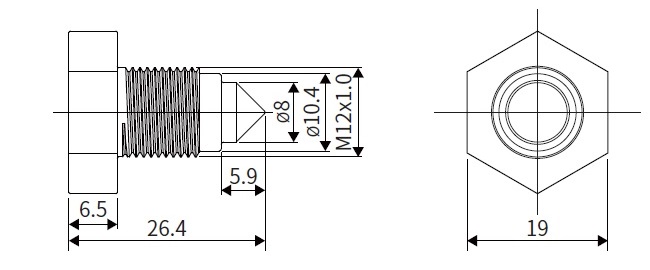

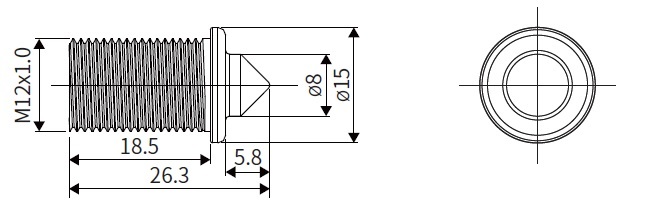

| Process Connection | M12x1.0 |

| Operating Temperature | -20 to 55°C |

| Operating Pressure | 7bar |

| Indicator Lamp | Orange |

| Accuracy | ±1mm |

| Supply Voltage | 10...30VDC |

| Current Consumptions (No load) | 10mA maximum |

| Output | NPN / PNP |

| Load Current (Max) | 100mA |

| Output Mode | normally open or closed in air |

| Electrical Protection | Activate delay time, reverse polarity protection, output short-circuit protection, output reverse connection protection |

| Response Time | 1ms |

| Ambient Light | Incandescent bulb:under 5,000lx / Sunlight:under 80,000lx |

| Lead Length | 30cm |

| Housing Protection | IP67 |

Mounted from inside

Mounted from outside

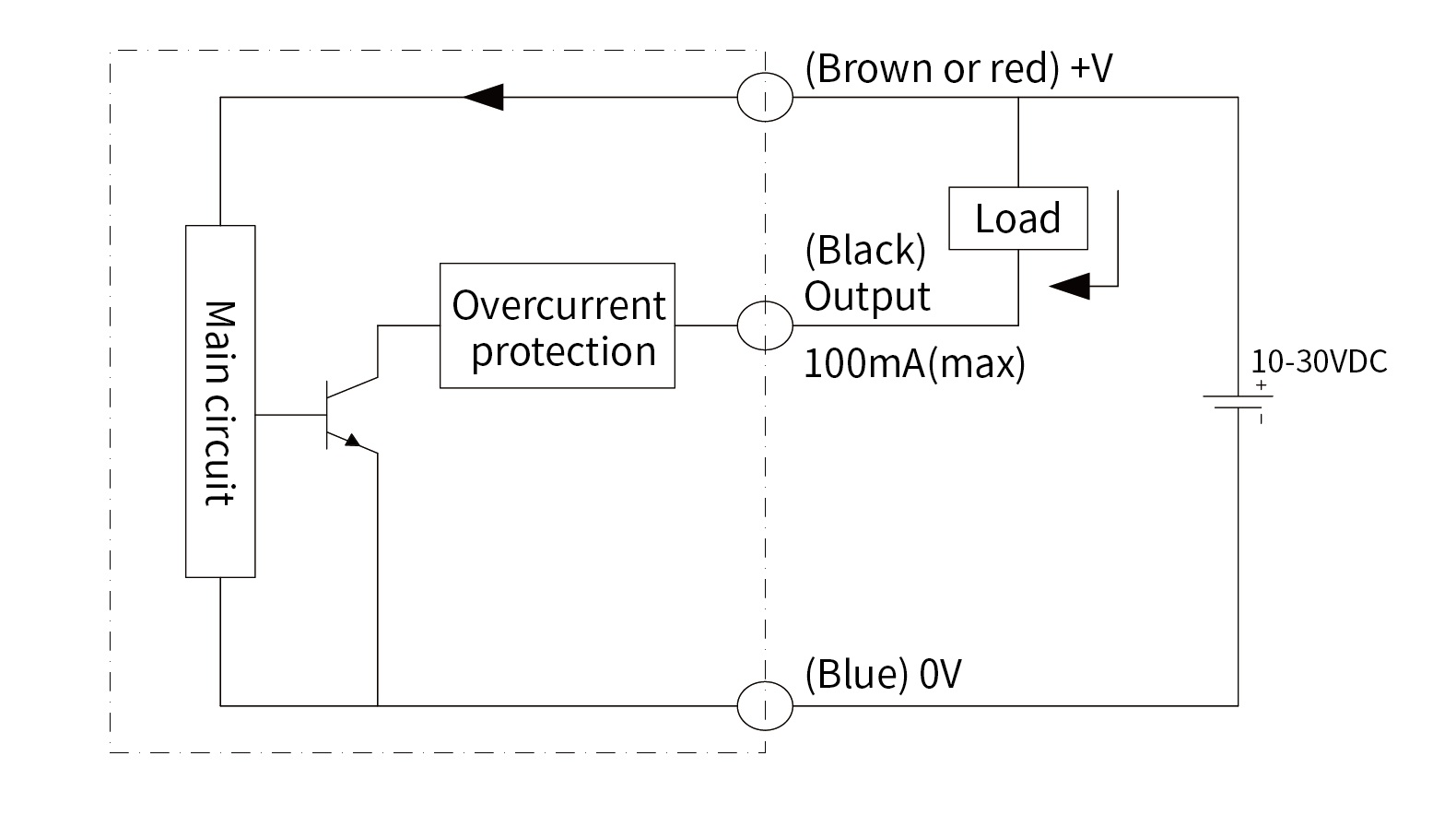

NPN open collector output

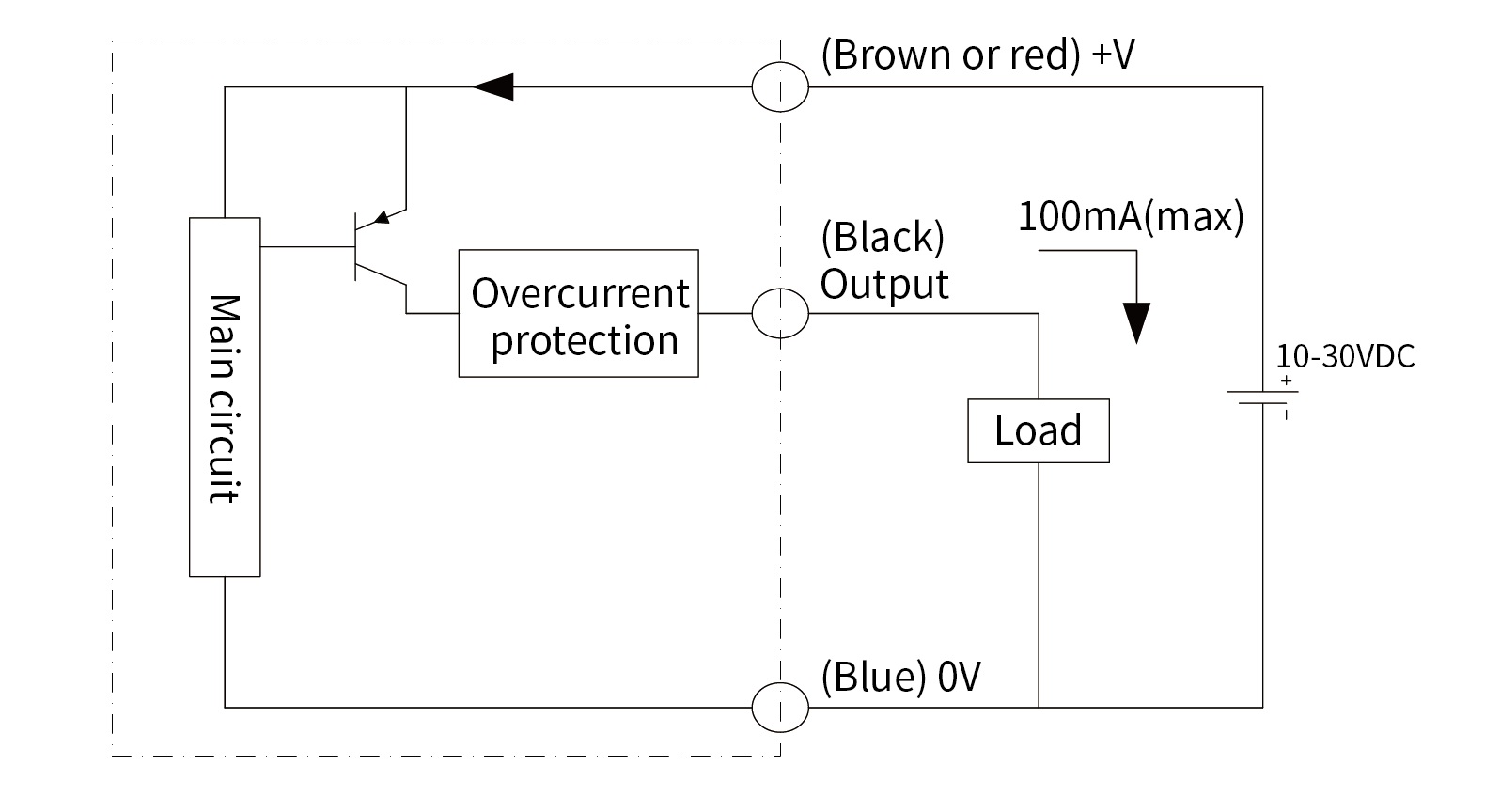

PNP open collector output

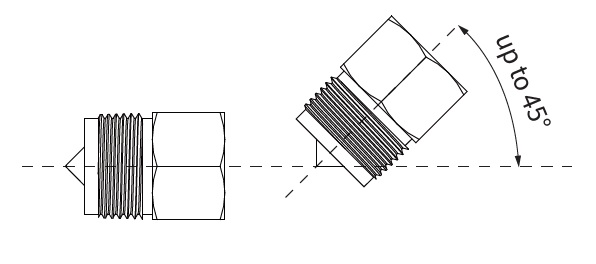

These units are designed for installing horizontally or up to 45° from horizontal only.

In many applications, people may need to measure or monitor liquid level. However, having moving parts is always a problem because there may be something that wears out or gets jammed. The optical level switch consists of two main parts: an infrared LED emitter and a light receiver. When the sensor is in air, light from the LED is internally reflected back to the receiver directly. When the liquid rises to cover the sensor tip, the transmitted light disperses and is refracted out into the liquid. Most of light is lost in liquid, on the other hand, only part of light will be returned to the receiver. Sensing this change, the receiver then triggers a switching operation to operate an external alarm or control circuit. The optical level switch is used for point level detecting and monitoring high or low level. For liquid level control, you can install two optical switches in upper and lower level of a tank or other type of container. When rising liquid immerses the upper optical level sensor, it will stop filling up liquid. On the other hand, when the liquid drops below the lower optical level sensor, it will start to fill in liquid. Therefore, the liquid level can be maintained between the upper and lower optical level switch.

Generally, it is difficult to detect milk level because milk is a kind of reflective liquid. When milk immerses the prism, the infrared light bounces off all of the fat particles and returns back. This situation makes the receiver think that it is in air again. However, we can provide a special type of optical level switch for milk detecting.

Mounted from inside

Mounted from outside